Roy Hill Iron Ore Project

Roy Hill Project has been designed to export 55 Mta of Iron Ore and includes Mine, Process Plant, Storage Yard, Heavy Railroad System from Mine

Roy Hill Project has been designed to export 55 Mta of Iron Ore and includes Mine, Process Plant, Storage Yard, Heavy Railroad System from Mine

Coarses stockyards including: Stacker for 2,400 tph Concentrates Stockyards including: 2 stackers for 1,500 tph

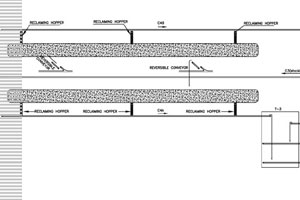

Two (2) Movable Berth Hoppers Belt Conveyor System 1,900 tph Warehouse storage for unloaded cargo Tripper conveyor with reversible cross conveyor Six reclaiming hopper with

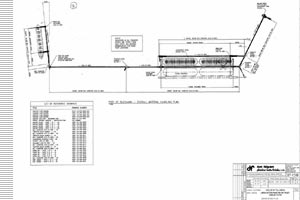

Turnkey supply of river barge loading terminal consisting of: Barge loading conveyors: BC01 and BC02: 800 TPH Loading hoppers with variable speed belt feeders: 4

Belt conveyor system. Capacities between 700 3,480 tph. Iron ore stacker 1,626 t/h and feeding belt conveyor. Pellet feed stacker 1,000 t/h and feeding belt

Seven Belt Conveyors, 2,000 t/h. Four Transfer Towers One Tripper Four Hoppers

Design, fabrication, procurement and supply of equipment for Iron Ore & Concentrate Handling Systems: Port Nine (9)Belt Conveyors. Capacities: Design Capacity 4,000-10,000 tph. Belt Width

Port Terminal for Shipunloading, storage yard and train loading, including following major equipment: Two ShipUnloaders 2,000 tph. Two Stacker / Reclaimer machines (4,000 / 2,500

Travelling, luffing, slewing and shuttling 5,000 STPH Shiploader for coal capable of loading bulk carriers from 40,000 up to 118,000 DWT. Designed for loading coal

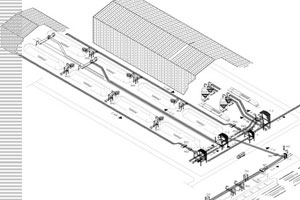

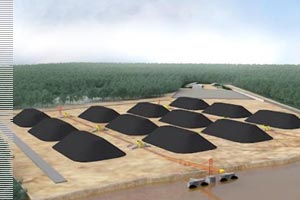

Turn Key supply of Coal Mine Storage Yard Conveyor System including: Two (2) Conveyors 2,500 tph. Two (2) Transfer Towers. One (1) Travelling Tripper two-

Two (2) Stacker-Reclaimer 3,250/1,750 tph. One (1) Stacker 3,250 tph. Six (6) Belt Conveyors 2,250 tph & Eight Belt Conveyors 3,250 tph. Two (2) Oversea

Belt conveyor system 2,400 tph Two unloading hoppers Two Stacker /Reclaimer machines 2,400/1,800 tph Train Loading Station 1,800 tph Dust Suppression System